Car rubber seal strips are flexible materials that are typically made from rubber or other elastomeric compounds. They are strategically placed around doors, windows, trunks, and other entry points of a vehicle. Their primary function is to create a tight seal when these openings are closed, preventing water, dust, dirt, wind, and noise from entering the car's interior.

In summary, the front door bottom seal strip may seem like a simple addition to a home or building, but its role in energy efficiency, comfort, and protection is significant. CE certification provides assurance that these strips meet stringent European standards, giving consumers peace of mind when making purchasing decisions. By investing in high-quality, CE-certified bottom seal strips, homeowners and businesses can enhance their comfort and efficiency while protecting their properties from the elements. As awareness of building performance continues to grow, the importance of such components cannot be overstated, making it a wise choice for any property owner.

Seal strips serve several essential functions in roller door applications. Firstly, they prevent the ingress of dust, dirt, and water, thereby maintaining a clean environment. This is particularly crucial in industrial settings where contamination can lead to severe repercussions. Secondly, seal strips help to improve thermal insulation, reducing energy costs associated with heating or cooling the space. This is particularly beneficial in climates that experience extreme temperatures. Lastly, seal strips also contribute to noise reduction, making them a vital aspect for residential areas where peace and quiet are paramount.

In summary, P seal strip suppliers are crucial players in today’s manufacturing and construction sectors. They provide high-quality, reliable products that enhance the performance of various applications. As industries continue to evolve, the demand for innovative sealing solutions will only increase. By fostering strong relationships with reputable suppliers, manufacturers can ensure that they remain competitive in their respective markets, driving efficiency, sustainability, and customer satisfaction. Choosing the right P seal strip supplier is more than just a transactional decision; it's an investment in quality, reliability, and the long-term success of a business.

Aluminium, known for its lightweight and durable properties, offers a number of advantages over traditional materials when used in door seals. One of the primary benefits is its excellent resistance to corrosion. Unlike steel or other metals, aluminium does not rust, which makes it an ideal choice for external doors that are exposed to varying weather conditions. Furthermore, the inherent strength of aluminium ensures that seal strips maintain their shape and functionality over time, leading to enhanced longevity.

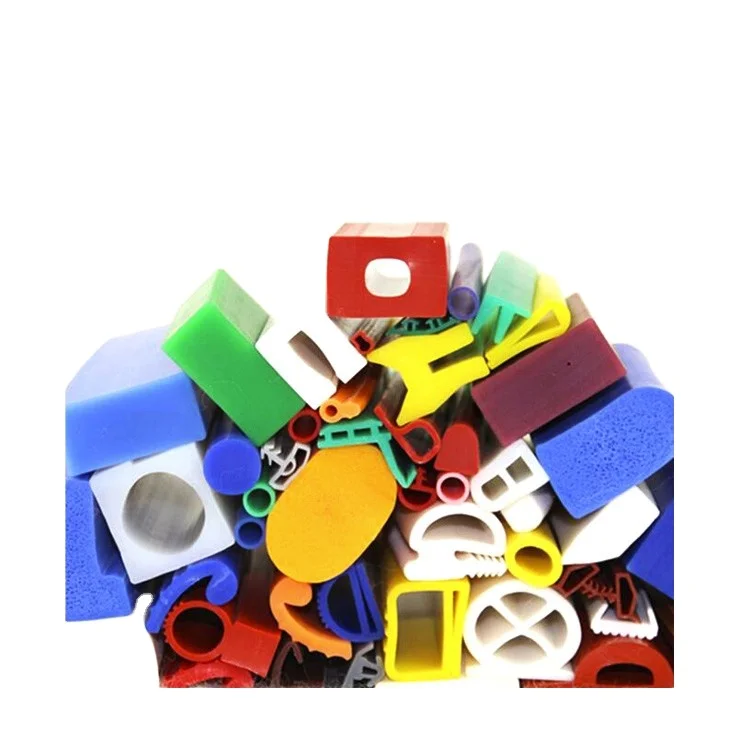

Seal strips, also known as sealing strips, are designed to fill gaps between surfaces, preventing the ingress of dust, water, air, and other contaminants. They are commonly made from materials like rubber, foam, and silicone, each tailored for specific applications. The choice of material and design depends on the particular requirements of the environment where the seal strip will be used, such as temperature extremes, exposure to chemicals, or mechanical stress.

Door seal strips are designed to fit snugly around the edges of doors, preventing drafts, water ingress, and dust from entering your home. They form a barrier that helps in maintaining a consistent indoor temperature, which is essential for energy conservation. In fact, improper sealing around doors can lead to significant energy loss, resulting in higher utility bills.